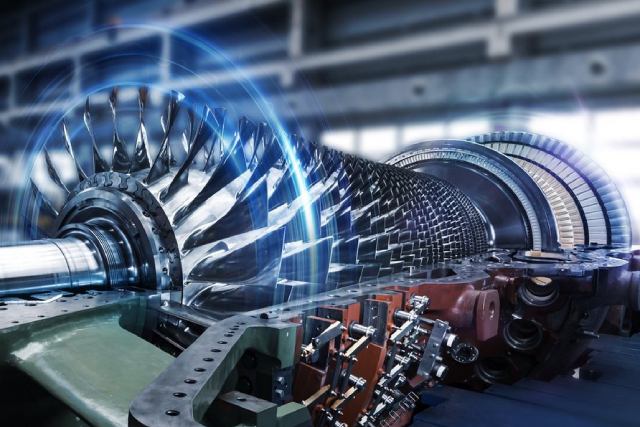

Condition Monitoring Services is the process of monitoring a parameter of condition in machinery (vibration, temperature etc.), in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance.

The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent consequential damages and avoid its consequences.

Condition monitoring has a unique benefit in that conditions that would shorten normal lifespan can be addressed before they develop into a major failure. Condition monitoring techniques are normally used on rotating equipment, auxiliary systems and other machinery (compressors, pumps, electric motors, internal combustion engines, presses), while periodic inspection using non-destructive testing (NDT) techniques and fit for service (FFS)[1] evaluation are used for static plant equipment such as steam boilers, piping and heat exchangers.

Effective condition monitoring using a combined service approach can ensure maximum asset life, minimum operating cost.

Benefits of Condition Monitoring Services

By minimising Condition Monitoring costs

By utilising Condition Monitoring techniques to maximise equipment performance and throughput

By improving Equipment Reliability through the effective prediction (and then avoidance) of equipment failures

By minimising downtime through the integrated planning and scheduling of repairs indicated by Condition Monitoring techniques with those indicated by other techniques.

By maximising component life by avoiding the conditions that reduce equipment life (for example, by ensuring ongoing precision alignment, minimal lubricant contamination etc.)

Why choose us ?

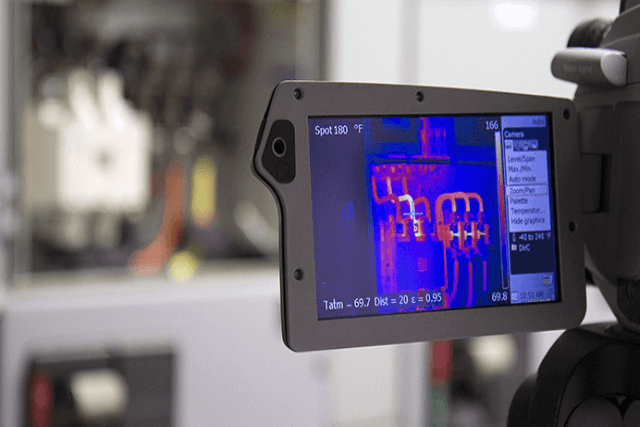

Fault detection in electrical distribution networks.

Our Condition Monitoring services provide your maintenance teams with the critical information.

We can tailor the service to meet your individual needs

We have over 20 years of experience with highly skilled engineers trained in every aspect of Condition Monitoring.

We have in-depth industry experience across a wide range of sectors with a proven track record of realising cost savings for our customers.

All equipment used by our engineers is maintained to relevant industry standards and manufacturers’ specifications.

Our Condition Monitoring services can be individually tailored to your needs, depending on the size of your site and the number of assets and system boundaries that have been defi ned within the scope of work.