Shock pulse method (SPM) is a technique for using signals from rotating rolling bearings as the basis for efficient condition monitoring of machines. From the innovation of the method it has been further developed and broadened and is a worldwide accepted philosophy for condition monitoring of rolling bearings and machine maintenance.

Measuring Operating Condition

The shock pulse meters measure the shock signal on a decibel scale, at two levels. A micro processor evaluates the signal. It needs input data defining the bearing type (ISO number) and the rolling velocity (RPM and bearing diameter).

Surface damage in bearings causes a large increase in shock pulse strength, combined with a notable change in the characteristics between stronger and weaker pulses. Shock values are thus immediately translated into measurements of relative oil film thickness or surface damage, whichever applies.

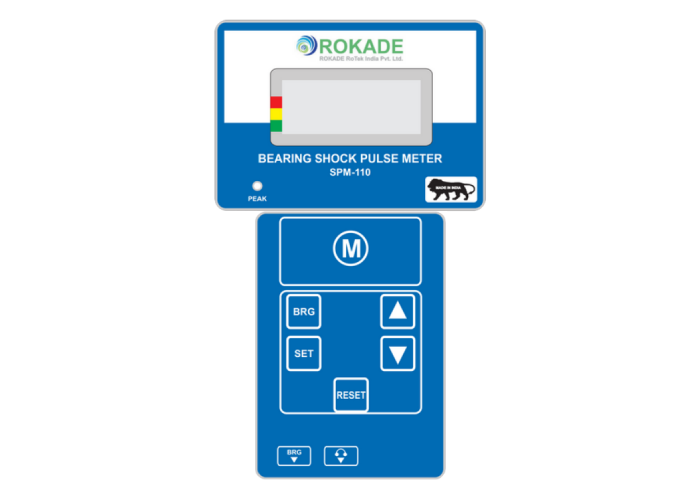

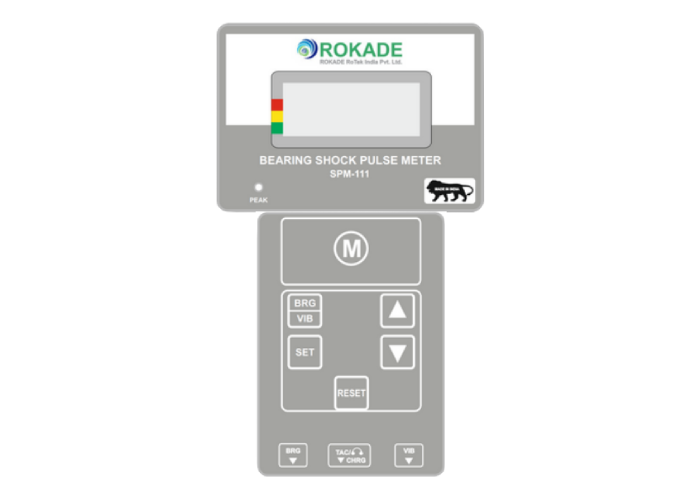

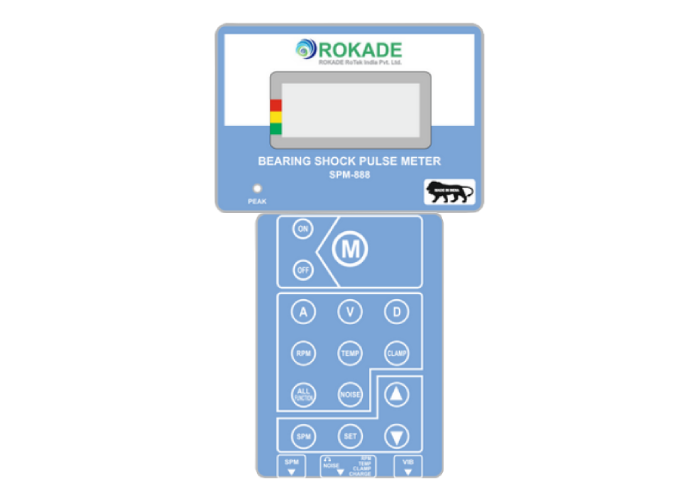

ROKADE Group has designed and manufactured various range of models depending upon customers requirements as follows