Cut waste oil in half

Fluid Intelligence’s vision is to change the way we use lubricant oils today. We help our customers to maximize their operational reliability and cut waste oil in half.

Lubrication costs heavy industry and logistics over $200bn annually and generates massive streams of waste oil as only fraction of that can be re-refined. Even with all these efforts machines break down and generate unnecessary downtimes and costs.

Wasted oil

Oil changes without need

Machine failures

Challenges with impurities and fluid quality

Massive cost

Oil, services, failures

See

Analyze

Recommend

Act

See

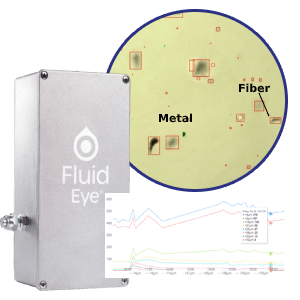

Oil images with performance data

Real-time microscopic view

Particle counting

Oil quality trend

Temperature, moisture & pressure

Analyze

Recommendations for actions

Real-time data synthesis & situation awareness

AI & machine vision analytics

Decision logic & alerts

Act

Immediate actions

Real-time oil regeneration

Failure mitigation

Production planning

Customer Benefits

50% less waste oil

Smaller waste oil streams for several customers

Reliability up

50% of customers avoided failure / downtime

Cost savings

10 first customers savings 1M euros

Customer Success Cases

Energy

Oil temp stabilization

Fluid Eye TREND

Oil analysis Extra insulation

200–300K€

No down-time

Hydro

Premature lube ageing prevention

Fluid Eye TREND

Varnish & side products removal Oil conditioning

Prevented 1/2 yr production loss

No down-time

Chemical

Extended oil change interval

Fluid Eye TREND

Oil analysis

33% of annual lube costs

No down-time

Manufacturing

Gear-box failure avoidance

Fluid Eye TREND

Impurity removal

50K€

No down-time

Pulp & paper

Reduced downtimes

Fluid Eye TREND

Oil analysis Impurity removal

Prevented down-time

Infra

Reduced down-times & failures

Fluid Eye TREND

Proactive strategy Mobile cleaning unit

100–200K€

Less oil changes Less down-time

Send Request

Download Catalogue