Types of Dynamic Balancing

Basically, all machines have some form of residual vibration. Enormous vibration in rotating machinery can cause high levels of noise and more importantly, significantly reduce the life of components. So, the ideal thing to do would be to remove all causes of vibration and allow the machine to run completely smooth. The process of balancing is the removal or addition of weight to the device, so that this effective mass centre approaches the true axis.

The goal of balancing is to minimize vibrations related to the first order. Basically, it works like this: We measure the initial state, then we add a trial weight of the known mass, calculate the position and mass of a counterweight, remove the trial weight and put the calculated weight on the opposite side, to cancel out the imbalance.

Single and dual-plane balancing

Depending on the machinery, single or dual plane balancing is used. Selecting one plane or two plane balancing generally depends on two factors. One of the factors is the ratio of the length of the rotor (L) to the diameter of the rotor (D). The other factor is the operating speed of the rotor. As a general rule of thumb, we can refer to the table shown below.

| Rotor | L/D Radio | Balance Correction | |

| Single Plane | Two Plane | ||

|

Less than 0.5 | 0-1000 RPM | Above 1000 RPM |

|

More than 0.5 | 0-500 | Above 500 RPM |

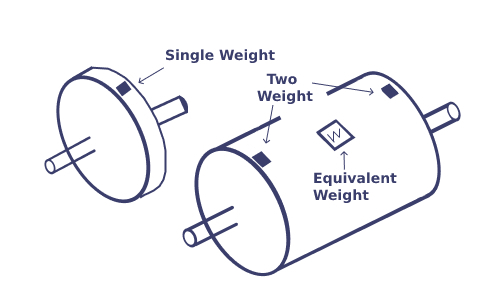

Single plane dynamic balancing

Single plane balancing is the placement of a weight in one plane to achieve an acceptable level of balance. All balancing that is done without spinning the component up to operating speed is said to be single plane balancing.

Single plane balancing using this technique has 3 steps

Initial round wherein initial amplitude and phase of vibration unbalance are measured

Trial round wherein a known trial weight is added at an arbitrary location and the corresponding change in amplitude and phase of unbalance is recorded.

Final round wherein correction weight and its location are calculated.

Two plane dynamic balancing

If we look at two planes balancing it is done in much the same manner as single plane balancing. The only difference is that two plane balancing needs special attention paid to the cross-effect, or correction plane interference.

Two-plane rotating Balance is the preferred method for Balancing Impellers when the width to diameter ratio is greater than 0.50. The narrow width of propeller Fans and narrow Impellers make plane separation impractical, and corrections are only made in one plane

About our services

We offer 24/7 Emergency In-House Dynamic Balancing Services at our factories at various locations in Western India, to serve any kind of Industries. One of our experienced engineers will always be on hand to take your call, no matter what time of day it is, talking to you about your balancing needs. We have decades of experience and have balanced a diverse range of rotating items in this time, including rotors, impellers, shafts, turbines, compressors etc.

Our balancing capacity

Weight: 0.5 kg to 30 tons

Diameter: upto 4 meters

Length: upto 13.5 meters

RPM: upto rated speed of 3500 RPM