Thermography Usage in Rotating and Stationary Equipment

Thermography, or infrared thermography, is a non-destructive testing technique that employs infrared imaging to visualize temperature variations in objects. This technology is pivotal for identifying anomalies, optimizing performance, ensuring safety, and extending equipment lifespan across diverse industries.

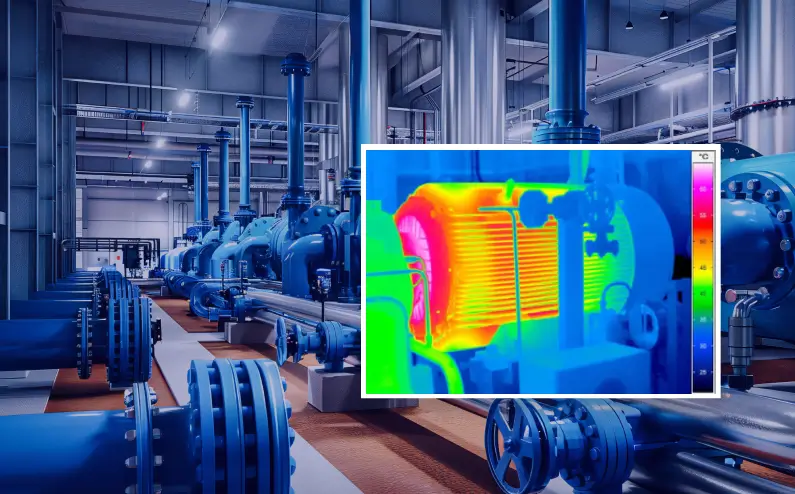

Thermography in Rotating Equipment

1. Bearing Health Assessment

While thermography is not the primary method for early detection of bearing faults, it can confirm bearing condition at advanced stages. Elevated temperatures indicate increased friction, which may result from lack of lubrication, misalignment, or wear. However, oil analysis and vibration analysis are preferred methods for detecting early signs of bearing wear, enabling proactive maintenance and minimizing downtime.

In case of unavailability of oil and vibration analysis programs, thermography will be the best predictive technique to detect bearing faults however it will be at very late stage before immediate audible sound and complete bearing failure stages.

2. Preventive Maintenance:

Regular thermographic inspections enable the early detection of anomalies in rotating equipment such as motors, pumps, and turbines. By monitoring temperature variations, operators can schedule maintenance activities like alignment, balancing, and lubrication proactively, optimizing performance and extending equipment lifespan.

3. Alignment and Balancing faults:

Thermography indirectly identifies misalignment or imbalance issues by detecting elevated temperatures in rotating components. However, specialized techniques like laser alignment and dynamic balancing are essential for precise measurement and correction. These methods ensure that shafts, couplings, and bearings are aligned correctly and balanced to minimize wear, vibration, and premature failure.

4. Electrical Components:

Thermography identifies hotspots in electrical components such as motors, generators, and switchgear. Elevated temperatures may indicate loose connections, overloaded circuits, or insulation defects, leading to potential electrical failures, fires, or safety hazards. Regular inspections enable timely intervention, ensuring equipment reliability and compliance with electrical standards.

5. Energy Efficiency:

Monitoring temperature variations in rotating equipment helps optimize energy consumption by identifying inefficiencies such as friction, misalignment, or wear. Overheating components consume more energy and may lead to premature failure. Thermography enables operators to address underlying issues, enhancing energy efficiency, reducing operational costs, and minimizing environmental impact.

Thermography in Stationary Equipment

1. Process Heater Tube Skin Temperature :

Thermography ensures uniform heat distribution across heater tubes in furnaces and boilers, optimizing combustion processes and preventing hotspots. Elevated temperatures indicate potential fouling, scaling, or insulation deficiencies, necessitating cleaning, maintenance, or insulation upgrades to maintain operational efficiency and safety.

2. Heat Exchangers:

Thermography detects fouling, blockages, or defects in heat exchangers, including tubes, plates, and fins. Early detection ensures structural integrity, prevents leaks, and optimizes heat transfer efficiency. By analyzing temperature profiles, operators can schedule maintenance activities such as cleaning, repair, or replacement, ensuring optimal performance and longevity.

3. Building Insulation and Energy Audits:

Thermography is utilized to inspect building envelopes for heat loss, moisture intrusion, and insulation deficiencies. By identifying energy inefficiencies, operators can improve building performance, reduce heating and cooling costs, and enhance occupant comfort and safety.

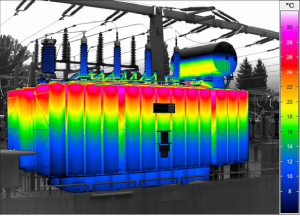

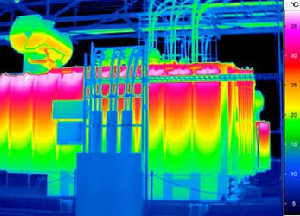

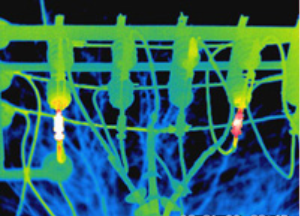

4. Electrical Distribution Systems:

Thermography identifies hotspots in electrical distribution systems, such as transformers, transmission lines, circuit breakers, and panels. Elevated temperatures may indicate overloaded circuits, loose connections, or insulation defects, leading to potential electrical failures or safety hazards. Regular inspections enable timely intervention, ensuring equipment reliability, compliance with electrical codes, and safety.

5. HVAC Systems:

Thermography is used to inspect HVAC components, including ductwork, vents, coils, and compressors. By identifying temperature variations, operators can optimize system performance, ensure proper airflow, and enhance energy efficiency. Additionally, thermography detects blockages, leaks, or malfunctions that may affect comfort levels, indoor air quality, and system reliability.

Conclusion

Thermography is a versatile technology that plays a pivotal role in monitoring and maintaining rotating and stationary equipment across various industries. By integrating multiple predictive maintenance techniques, operators can maximize efficiency, minimize downtime, and ensure compliance with safety standards and regulations. Regular thermographic inspections and proactive maintenance practices are essential for optimizing performance, ensuring safety, and extending the operational lifespan of equipment.