What is Dynamic Balancing?

What is Dynamic Balancing?

Dynamic balancing is a way of balancing machines by rotating parts quickly and measuring the imbalance using electronic equipment. The imbalance measured can then be corrected by adding or subtracting weight from the rotating parts until the vibration is reduced."

Basically, all machines have some form of residual vibration. Enormous vibration in rotating machinery can cause high levels of noise and more importantly, significantly reduce the life of components. So, the ideal thing to do would be to remove all causes of vibration and allow the machine to run completely smooth. The process of balancing is the removal or addition of weight to the device, so that this effective mass centre approaches the true axis.

In addition to dynamic balance, there is also static balance. When a part is statically balanced, the centre of gravity is on the axis of the rotation. This means the part will stay stationary at a horizontal axis, without the application of braking force. It also has no tendency to rotate due to the force of the gravity.

Reasons you might require dynamic balancing

Noise reduction

Impeller erosion

Extended motor life

Increased performance

Vibration reduction/ elimination

To remove dirt build-up

Thermal and mechanical distortion

Mismatched lengths of keys and keyways

Previous balancing attempts have been unsuccessful

Internal part corrosion

Parts haven’t been assembled properly

Casting imperfections, voids and inclusions

Shifting mass due to loose parts or poorly tapered hub fits

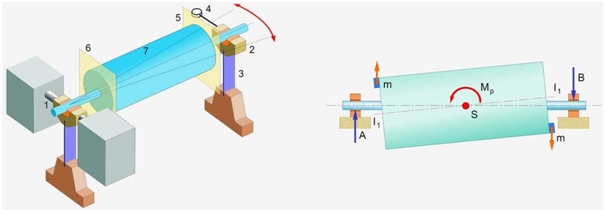

(How balancing machine works: 1=hard-bearing, 2=soft bearing, 3=spring, 4=vibration sensor, 5 & 6=balancing planes, 7=rotor)

(How balancing machine works: 1=hard-bearing, 2=soft bearing, 3=spring, 4=vibration sensor, 5 & 6=balancing planes, 7=rotor)

The ultimate goal in any piece of equipment is to have it operating free of any vibration while running smoothly for a long time. In reality, however, vibration is always going to be a part of any rotating machinery, and certain levels of vibration may even be acceptable. Rather than trying to remove all vibration from the machinery, it is beneficial to seek to balance the machinery to the greatest extent possible. This reduces vibration to the point of reduced noise levels, and the existing vibration doesn’t affect machine life.

Dynamic balancing is performed with sensors attached to the bearing pedestals. It allows for the identification of the imbalance on two planes so that a real correction can take place. It makes use of machinery to identify the point of the imbalance and correct it. Other factors to consider are the length of the machine as well as its operating speed.

Benefits of balancing:

Increased service life of machinery

Ensure compliance with industry regulations

Improve performance and efficiency of machinery

Improvement of safety of your team

Reduction of costly downtime that comes from premature machine breakdowns

About our services

We offer 24/7 Emergency In-House Dynamic Balancing Services at our factories at various locations in Western India, to serve any kind of Industries. One of our experienced engineers will always be on hand to take your call, no matter what time of day it is, talking to you about your balancing needs. We have decades of experience and have balanced a diverse range of rotating items in this time, including rotors, impellers, shafts, turbines, compressors etc.

Our balancing capacity

Weight: 0.5 kg to 30 tons

Diameter: upto 4 meters

Length: upto 13.5 meters

RPM: upto rated speed of 3500 RPM