Dynamic Balancing of Rotor

Rotor Dynamic balancing has a direct effect on the life of any Rotating Machine and productivity. The degree to which a Rotor is out of balance is referred to as imbalance. Rotor imbalance creates force on the bearing assembly, resulting in vibration and heat, which directly affects the Machine performance.

Basically, all machines have some form of residual vibration. Enormous vibration in Rotating Machinery can cause high levels of noise and more importantly, significantly reduce the life of components. So, the ideal way to do would be to remove all causes of vibration and allow the Machine to run smoothly. The process of balancing is the removal or addition of weight to the device, so that this effective mass center approaches the true axis.

Dynamic balancing as per IS1940/1 at Grade 2.5

Diameter - 1800 mm

Weight - 5500 kg

Length - 2100 mm

Speed - 300 RPM

Scope Of Work Involved In Propeller Repair

Rotor received at rabale, navi mumbai factory

Set-up of rotor on balancing machine

Checking of un-balance on cab instrument

Unbalance mass correction by welding process

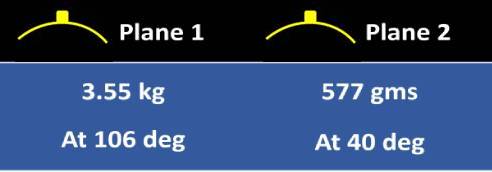

Mass correction by adding method on plane 1 & 2

Job ready for dispatch

Process Followed Dynamic Balancing Of Gas Turbine Rotor Is Briefed Below:

Step:1

Rotor received at rabale, navi mumbai factory.

Step:2

Set-up of rotor on balancing machine.

Initial run – initial imbalance level measured.

Step:3

Unbalance mass correction by welding process.

Step:4

Mass correction by adding method on plane 1 & 2.

Final run – final imbalance level achieved.

Step:5