Dynamic Balancing Of Gas Turbine Rotor

Gas turbine is a combustion engin that can convert natural gas or other liquid fuels to mechanical energy. This energy then drives a genrator that produces electrical energy. It is electrical energy that moves along power lines to homes and businesses

Gas turbines are used to power aircraft, trains, ships, electrical genrators, pumps, gas compressors, and tanks.

Dynamic balancing as per IS1940/1 at Grade 1

We have recently worked with following details

Diameter- 850 mm

Weight- 748 kg

Length- 2750 mm

Speed - 1250 RPM

Scope Of Work

Fan received at our Rabale, Navi Mumbai factory.

Unloading of the Turbine Rotor from vehicle.

Job lifting using 30 tons crane.

Set-up for job on machine.

Dynamic balancing process being carried out.

Balancing correction by mass adding.

Job ready for dispatch.

Process followed Dynamic balancing of gas turbine rotor is briefed below:

Step:1

Physical inspection of gas turbine

Step:2

Initial Dynamic balancing process being carried out on SCHENCK Machine.

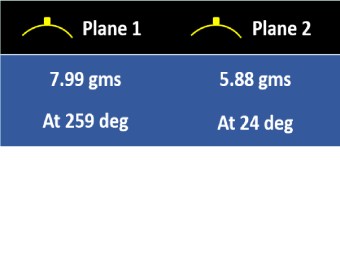

Initial un-balance level is checked, after setting-up CAB Instrument which is connected with the Dynamic Balancing Machine.

Step:3

Unbalance correction marking

Step:4

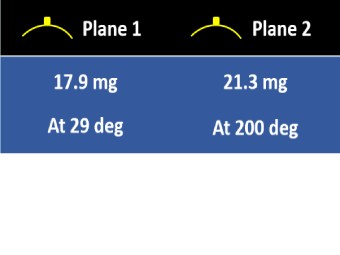

After correction final run is carried out to check the final readings which are under permissible limit as per IS1940/1 at Grade 1

Post balancing, final un-balance level achieved, is shown on cab instrument.

Step:5

After Dynamic Balancing, the Job is kept ready for dispatch

Case Study

Relevant Services

Dynamic Balancing

Dynamic balancing is a way of balancing machines by rotating parts quickly and measuring the imbalance. The imbalance measured can then be corrected

Rotor Repairs

Remote Vibration and Condition Monitoring it is the process of monitoring a parameter of condition in machinery (vibration, temperature, speed, current etc.)